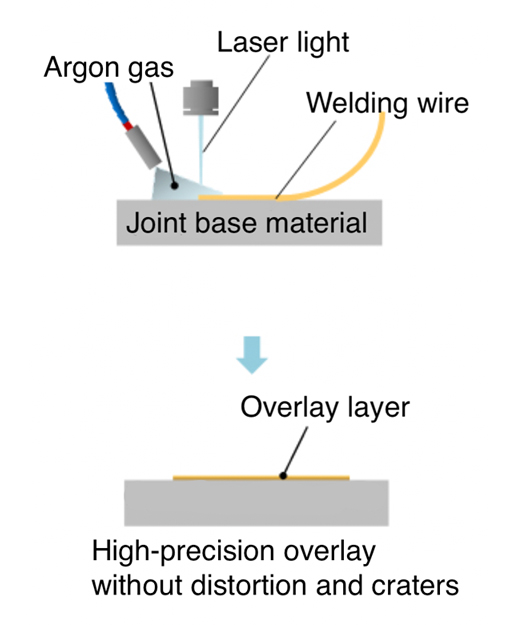

We compared the characteristics of Laser Welding with those of TIG Welding.

Image of Welding

Laser Welding

TIG Welding

Figure: Laser Welding and TIG Welding laser

Advantages of each

Laser Welding

- Easy to operate.

- Low heat input results in fewer craters, and less distortion, and oxidation, and allows for high-precision overlays.

- It is possible to build up narrow grooves, fillets at internal angles, bottoms of holes, etc.

- No need for preheating or post-heating.

TIG Welding

- Fast build-up speed.

- Overlay can be applied not only downward but also upward.

- A large amount of overlay can be applied over a wide area in a short time.

Disadvantages of each

Laser Welding

- Wide Welding large areas is slow and time consuming.

- Cost may not meet your needs without negotiations with customers.

TIG Welding

- Requires skill.

- Large heat input.

(large distortion /craters) - Large overlay welding surplus.

(finishing time and cost are required)

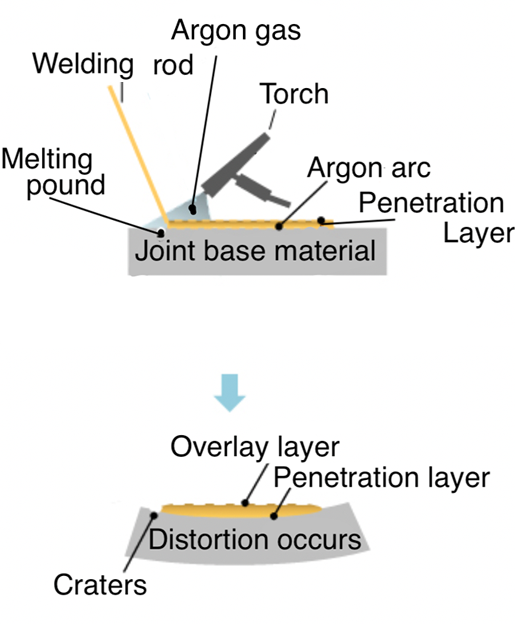

Welding type and characteristics

Table: Welding type and evaluation at Yoshimura Welding Station

TIG Welding, often used for a wide range of overlay welding applications including base and runner parts outside of product parts, allows for upward welding-typically considered challenging-with excellent operability.

On the other hand, Laser Welding enables precise overlay welding in units of 0.1mm.

Especially in product parts where high accuracy is required, it is most suitable for overlay welding to compensate for sink marks generated in TIG Welding, which are a serious cause of welding defects.

From the old and new welding technologies introduced by us, we can propose the most cost-effective mold welding for our customers.

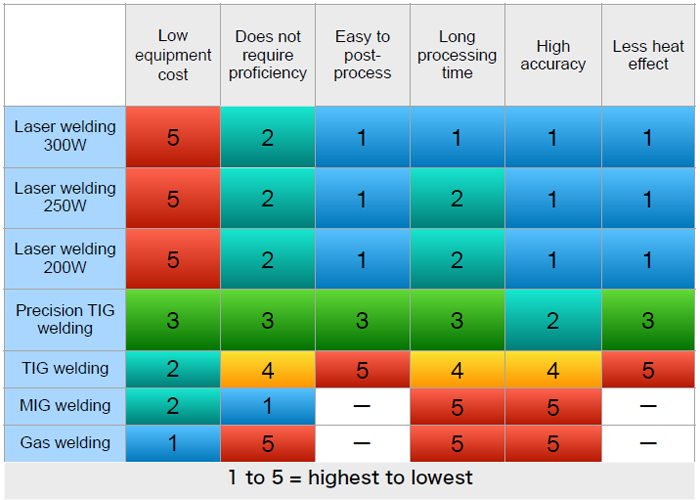

Overlay welding of molds & dies.

We mainly perform overlay welding of molds & dies.

In general, welding has the image of joining members together, but overlay welding is a welding technology as a surface treatment technology.

Image of cornered overlay welding

Purpose of overlay welding of molds & dies at our company

- Repairing and restoring damaged parts.

- Overlay welding is performed to reuse parts due to design changes.

Case1: Specific engraved characters are overlaid and welded onto the mold. When changing from ‘2023’ to ‘2024’, it is possible to overlay only ‘3’ of ‘2023’. - The surface layer of the mold is made of a welding material with excellent properties to improve the life of the mold.

Case2: When surface characteristics such as impact force resistance or friction resistance are required, overlay welding suitable welding material is performed.

Welding art

Since 2006, we have used welding art to showcase samples of our Laser Welding.

This is because it is easier for people to understand the work that we do by looking at real objects rather than explanations.

There are unlimited possibilities to create pieces. I can create pieces with or without blueprints.

Please tell us what you are looking for. We may be able to help you.

Trophy

Object: Trophy

[Largest size: Width190 x Depth190 x Height360 (mm)]

I created a trophy for the first EXCELUZ Championship.

It is a football academy championship to which my son is very much indebted. It took about two months from planning to completion, and I made it out o f gratitude.

When one player said to me ‘I want a trophy’ I was deeply moved by how good it was to make it. I would like to thank everyone at EXCELUZ for giving me such an opportunity.

Heart

Object: Heart

[Size:Width70 x depth40 x height80 (mm)]

My son (12 years old at the time) had heart surgery because o f a congenital disorder. After that, he became healthy.

With expectations, anxiety, and gratitude, I created and expressed the ‘ heart ’ using Laser Welding.

We mainly use Φ0.3mm welding wire.

It vibrates 60 times a minute in the image of a heartbeat.

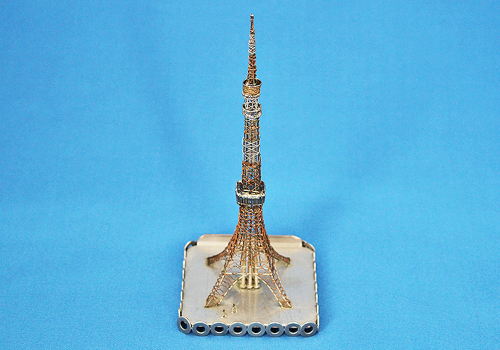

Tokyo Tower

Object: Tokyo Tower

[Size:Width80 x depth80 x height190 (mm)]

I made it for my childhood friend in Miyazaki prefecture, hoping that he would cherish the seven years he worked in Tokyo.

I used ‘welding art’ to express and present the ‘Tokyo Tower’ that we both climbed together.

Sea creatures

Object: Sea creature

[Size:Width110 x depth 75 x height 90 (mm)]

A gift for my wife to commemorate the 10th anniversary of our marriage.

We are full of gratitude for the beautiful nature of Zamami in Okinawa, where we met, and for the locals there.

I made it as welding art using all the skills at that time.